3D Optical Profilometers

3D Optical Profilometers

The Profilm3D® benchtop optical profiler and Zeta™ optical profilometers provide fast, easy, non-contact solutions for 3D surface topography measurements. Our portfolio of 3D optical profilers supports a variety of measurement techniques, including white light interferometry, True Color imaging and ZDot™ confocal grid structured illumination. KLA Instruments can help guide you to the right 3D optical profiler solution for your unique measurement needs.

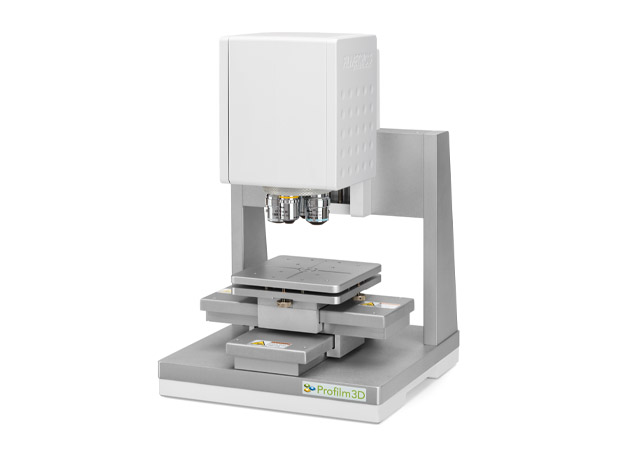

Filmetrics® Profilm3D® Optical Profilometer

The Profilm3D® benchtop optical profiler utilizes white light interferometry, TotalFocus® infinite depth-of-field imaging, or Enhanced Roughness Mode to provide easy, non-contact measurement of 3D step heights, roughness, and other surface topography.

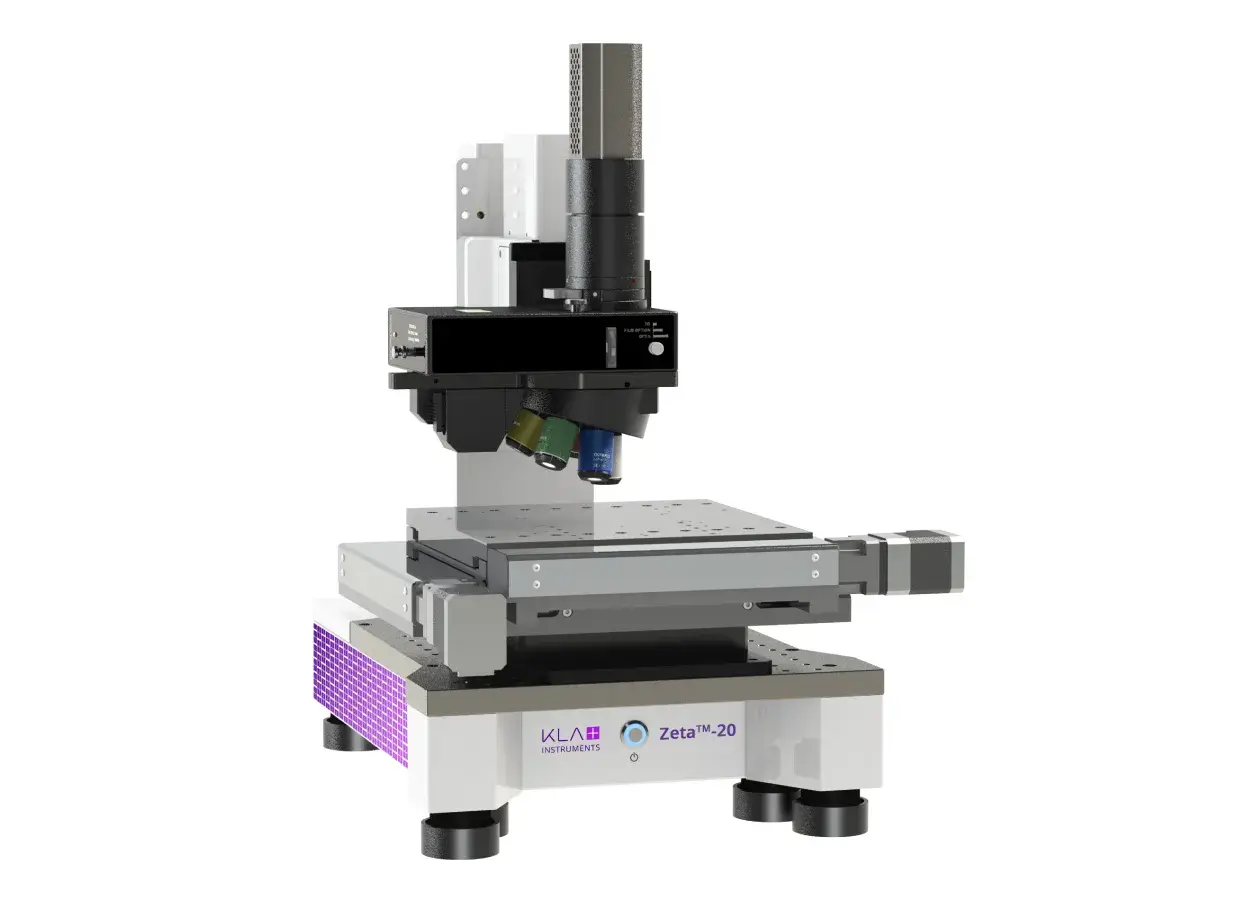

Zeta™-20 Optical Profiler

The Zeta-20 benchtop 3D non-contact optical profilometer features patented ZDot™ technology and flexible multi-mode optics for measurement of 3D surface topography, film thickness and automated defect inspection. The High Resolution HR configuration is designed specifically for advanced solar applications.

Zeta™-300 Optical Profiler

Building upon the proven performance of the Zeta-20, the Zeta-300 non-contact 3D optical profiler includes integrated vibration isolation and support for larger sample sizes to meet your R&D and production requirements.

Zeta™-388 Optical Profiler

The Zeta-388 non-contact 3D optical profiler combines the Zeta-300 system with a cassette-to-cassette wafer handler, pattern recognition, automated data analysis and SECS/GEM to support production measurement requirements.

Looking for stylus surface profilometers?

View MoreTechnical Literature

Browse application notes and technical papers from KLA Instruments Application Engineers and customers, covering a variety of use cases for KLA Instruments products.

Timeline of Innovation

The history of the optical profiler portfolio of KLA Instruments™ is a story of innovation from diverse origins. ADE launched the MicroXAM interferometer. Zeta™ Instruments developed ZDot™ and multi-mode optical profilers. Filmetrics® introduced novel, general-purpose white-light interferometers. These products came together into a diverse portfolio of optical profilometers, now unified under the KLA Instruments brand. Learn more about our rich history of innovation and how our tools continue to evolve to support your surface metrology requirements.

Receive the latest KLA Instruments news, papers, events, and more

Follow KLA Instruments

Follow KLA Instruments to engage with our experts and learn about our tool applications.