Reticle qualification, Reticle process control, Reticle process equipment monitoring, Outgoing reticle quality check

Reticle Manufacturing

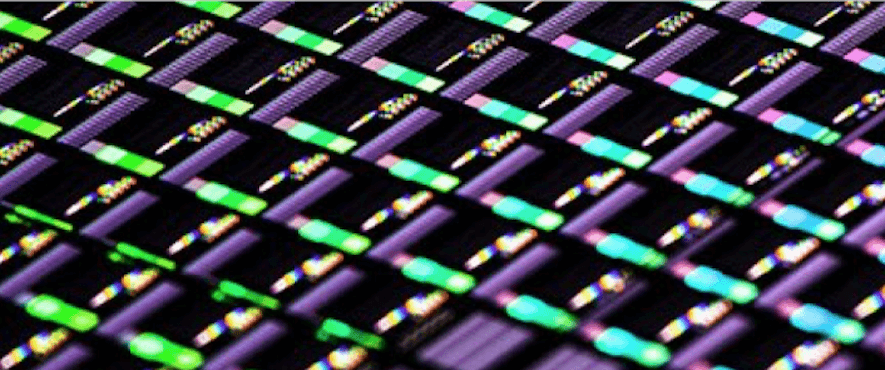

An error-free reticle (also known as a photomask or mask) represents a critical element in achieving high semiconductor device yields, since reticle defects or pattern placement errors can be replicated in many die on production wafers. Reticles are built upon blanks: substrates of quartz deposited with absorber films. KLA’s portfolio of reticle inspection, metrology and data analytics systems help blank, reticle and IC manufacturers identify reticle defects and pattern placement errors, thereby reducing yield risk.

Product Category

Teron™ 6xx

Reticle Defect Inspection Systems for Mask Shop Applications

The Teron™ 640e reticle inspection product line advances the development and qualification of leading-edge EUV and 193nm patterned reticles in mask shops by detecting critical pattern and particle defects. Using die-to-database or die-to-die modes, these inspection systems are designed to handle the wide range of stack materials and complex OPC structures characteristic of the latest 7nm and 5nm device nodes. The Teron 640e incorporates several optics and image processing enhancements that support the defect capture specifications and throughput required to accelerate reticle manufacturing cycle times. The Teron 640e product line also achieves the stringent cleanliness requirements necessary for production of EUV masks.

Teron 640

Industry production standard for inspection of optical and EUV reticles at the 10nm node and beyond.

Teron 630

Industry production standard for inspection of 1Xnm / 2XHP optical and EUV reticles.

Teron 610

Industry production standard for inspection of 2Xnm / 3XHP optical reticles.

Teron™ SL6xx

Reticle Defect Inspection Systems for IC Fab Applications

The Teron™ SL670e XP inspection system is used to assess incoming EUV reticle quality and to re-qualify EUV reticles periodically during production use and after reticle cleaning, helping chipmakers protect yield by reducing the risk of printing defective wafers. With innovative EUVGold™ and EUVMultiDie technologies, advanced focus tracking, and imaging flexibility, the Teron SL670e XP delivers the sensitivity required to monitor and detect yield-critical reticle defects on EUV reticles used for 5nm/3nm logic and advanced DRAM chip production. The Teron SL670e XP also has industry-leading production throughput, supporting the fast cycle times needed to qualify reticles during high-volume chip manufacturing. Inspection of advanced optical reticles is supported on the Teron SL670e XP with an option.

Reticle re-qualification, Incoming reticle quality check

Teron™ SL670e:

Inspection of EUV and optical (optional) reticles during chip manufacturing for 7nm/5nm design node IC technologies.

RA (Reticle Analyzer):

Reticle data analytics system for IC fabs supports applications such as automatic defect classification, lithography plane review and defect progression monitoring.

Teron™ SL655:

Inspection of optical and EUV (optional) reticles during chip manufacturing for 10nm design node IC technologies.

Teron™ SL650:

Inspection of optical reticles during chip manufacturing for 20nm design node IC technologies.

TeraScan™ 597XRS

Reticle Defect Inspection Systems for Mask Shop Applications

The TeraScan™ 597XRS reticle inspection system is the most comprehensive, low-cost-of-ownership reticle defect inspection solution for ≥32 nm design rules. With sensitivity to detect classical defects (intrusions, extrusions, and point defects), the TeraScan 597XRS can inspect numerous reticle types including chrome-on-glass, sub-resolution optical proximity correction (OPC), embedded phase shift, and alternating phase shift, at both 248 nm and 193 nm wavelengths. Using deep ultraviolet (DUV) image acquisition with proven Tera inspection algorithms, TeraScan’s low false defect rate and high-speed pattern inspection make it ideal for pre- and post-pellicle pattern inspection in photomask manufacturing operations, and for incoming quality control in wafer fabs.

Reticle qualification, Reticle process control, Reticle process equipment monitoring, Outgoing reticle quality check

X5.x™

Reticle Defect Inspection Systems for IC Fab Applications

The X5.x™ reticle inspection systems capture defects and pattern degradation required for early detection of haze and other progressive defects that occur unpredictably on masks in production in the fab. Because such defects threaten the yield of every subsequent lithographic field and wafer printed, early capturing the reticle defects before they are printed on the wafer is the best means of protecting yield. Once a contaminated reticle is cleaned, it is re-inspected to re-qualify it for the production line. Total ReQual extends reticle re-qualification beyond defect detection to incorporate other changes that may happen during a reticle’s lifetime in the fab. Degradation in the pattern from repeated cleaning or exposure may begin to narrow the process window. Early detection of changes to the mask pattern can be critical for maintaining device yield, performance and reliability. Lastly, many leading fabs use the X5.x reticle inspection systems to verify the specs of reticles delivered to the fab, to check for defects added during shipment, to benchmark vendors, or as part of a routine quality-control program.

Reticle re-qualification, Incoming reticle quality check

X5.2

- CoO solution for reticle defects/degradation monitoring ≥2X nm design rule

- Pixel flexibility and upgradeability options

- STARlight™ mode provides superior coverage and performance on a wide variety of masks

- iCDU option for Intensity-based CDU monitoring

- Reticle Analyzer: Automated Defect Classification and Printability

- Industry-proven 5xx platform

X5.3

- Enhanced Productivity: Over 30% Faster scan time vs. X5.2

- Field upgradeable from X5.2

- Pixel flexibility and upgradeability options

- Advanced multi-algo suite

- STARlightMaps™ for CDU monitoring

- Multiple productivity options for flexibility including pixels and modes

- Industry-proven 5xx platform

FlashScan®

Reticle Blank Defect Inspection Systems

The FlashScan® 211 mask blank defect inspection system supports mask shops and blank manufacturers in meeting mask blank defect requirements for optical and EUV lithography applications. The FlashScan 211 system pairs its high sensitivity with unparalleled inspection speed and automatic defect dispositioning, reducing the time to results for a wide range of applications.

Mask blank manufacturing, Mask blank qualification, Reticle process control, Reticle process equipment monitoring

LMS IPRO

Reticle Pattern Registration Metrology Systems

The LMS IPRO7 reticle registration metrology system is designed to provide accurate and fast verification of the pattern placement performance on EUV and optical reticles for the 7nm design node. By offering comprehensive characterization of reticle pattern placement error, the LMS IPRO7 produces data used for e-beam mask writer corrections and reticle quality control during the development and production of advanced design node reticles. Using KLA’s proprietary model-based metrology algorithm, the LMS IPRO7 measures pattern placement error for both targets and multiple on-device pattern features with high accuracy, enabling characterization and reduction of reticle-related contributions to device overlay errors in the IC fab.

Reticle qualification, Outgoing reticle quality check, Mask writer qualification and monitoring, Reticle process monitoring, Wafer patterning control

LMS IPRO6:

Mask metrology system for the 10nm design node, supporting measurement on both standard registration marks and on-device pattern features.

LMS IPRO4:

Mask metrology system for the 32nm/28nm design nodes. With industry-unique flexible handling capability, the LMS IPRO4 supports mask sizes from 4” to 8”. Click the Contact Us button for more information about new and refurbished systems.

MaskTemp™

In Situ Reticle Temperature Measurement System

The MaskTemp™ 2 in situ reticle temperature measurement system is used by mask shops for qualification and monitoring of e-beam writers and high temperature reticle process steps. The MaskTemp 2 serves a key role in the qualification of e-beam mask writers as extreme temperature stability is required over the extended time period (up to 24 hours) required to completely write a mask. Inside the e-beam mask writer, the MaskTemp 2 collects temperature data for 24 consecutive hours, providing mask manufacturers with the data needed to ensure the thermal stability of the system prior to writing critical masks. The MaskTemp 2 also supports post-exposure bake characterization, hot plate temperature uniformity monitoring, hot plate matching, and other high temperature process applications, helping mask manufacturers identify and reduce post-write process thermal variations that affect final reticle quality.

e-Beam mask writer qualification, Process development, Process control, Process qualification, Process monitoring, Process tool qualification, Process tool matching

e-Beam mask write | 20-40°C

Post-exposure bake | 20-140°C

Software Solutions

KLA has several Software Solutions that support Reticle Manufacturing, including RDC and Klarity®

Are you sure?

You've selected to view this site translated by Google Translate.

KLA China has the same content with improved translations.

Would you like to visit KLA China instead?

您已选择查看由Google翻译翻译的此网站。

KLA中国的内容与英文网站相同并改进了翻译。

你想访问KLA中国吗?

If you are a current KLA Employee, please apply through the KLA Intranet on My Access.