The new Orbotech Corus™ 8M direct imaging (DI) system is the first solution built on KLA’s all-in-one revolutionary Orbotech Corus platform, combining optimized resolution, accuracy and efficiency for PCB manufacturers designing smaller, thinner devices for OEMs that pack ever-increasing functionality into increasingly small enclosures for high-end applications.

“Premium smartphones exemplify the trend toward increased capability paired with sleeker, compact designs that couldn’t be achieved without major advancements for PCBs and IC substrates. DI technology is hugely instrumental in this shift, and our all-in-one Orbotech Corus platform will produce the accurate, super-fine features required by these evolving technological innovations with greater capacity and efficiency.”

Arik Gordon, general manager, LIS division, KLA

Manufacturers use DI technology to produce advanced PCBs and IC substrates designed with extremely thin conductors and transmission lines. These copper traces must be formed with extreme precision, as circuit density increases and the distance between lines grow narrower.

“This is no easy feat given the inherent challenges of defining, forming and handling these delicate circuits at high production throughput,” Gordon says. “Our engineering team developed the extendable Orbotech Corus platform as an innovative, fully automated, double-sided system to provide the direct imaging capability required to accelerate a wide number of industrial and communication applications that rely on the manufacturing of high-density interconnect PCBs and IC substrates.”

Orbotech Corus is a Leap Forward in DI Technology

KLA designed the Orbotech Corus 8M direct imaging system to deliver enhanced performance through improved accuracy and efficiency:

All-in-One to Boost Efficiency and Yield

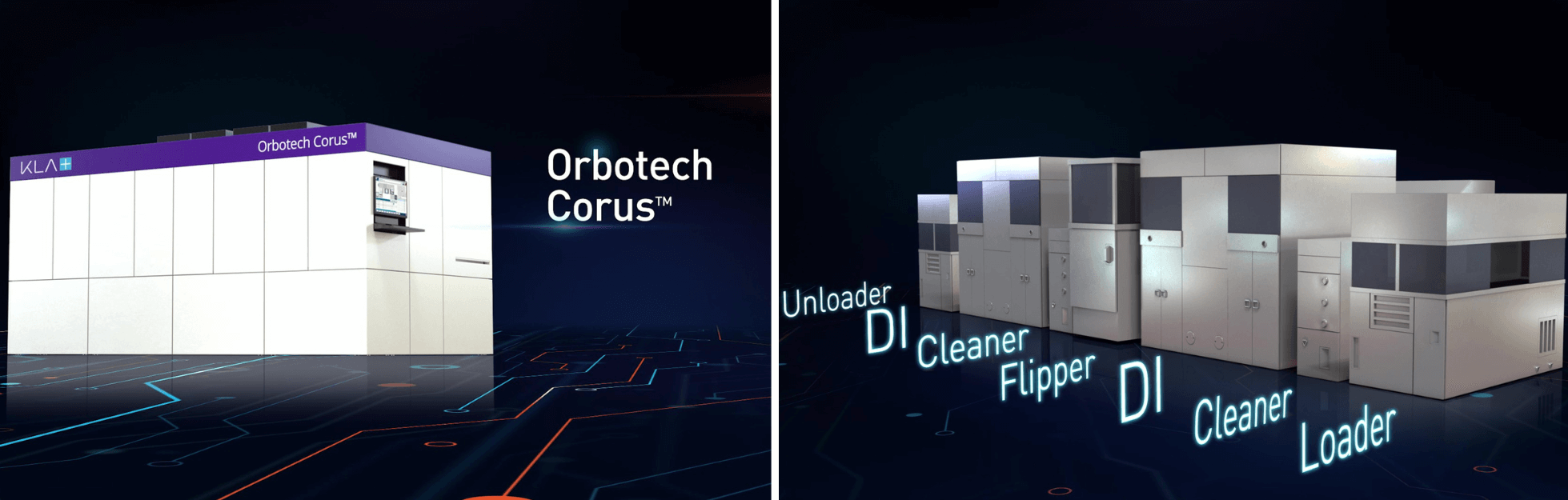

Orbotech Corus DI systems feature Double-Sided Imaging (DSI™) technology, an industry-first innovation that enables the imaging of both sides of the PCB panel, eliminating the need for multiple independent DI, loader/unloader and flipper systems. This means that a single, fully automated Orbotech Corus 8M DI system can effectively replace a complete DI production line.

This all-in-one approach to direct imaging delivers additional benefits, such as higher capacity per square meter in a physical footprint that conserves valuable cleanroom floor space. Whereas a conventional DI line might measure approximately 18 square meters, an Orbotech Corus 8M DI system reduces this footprint to nearly 10 square meters.

The fully integrated system reduces contamination risk by including integrated cleaners and filters, all in an enclosed, compact “box” that helps provide manufacturers with a clean environment throughout the system. Manufacturers will see even higher cleanliness in the exposure area of the tool to maintain high yield levels.

High Accuracy and Precise Imaging for Increased Patterning Quality of Fine Lines

Orbotech Corus 8M DI systems significantly enhance the field-proven Large Scan Optics (LSO™) and MultiWave™ Laser technologies by utilizing a higher power laser and more sophisticated optics. This optimized optics path enables high depth-of-focus (DOF) for improved line precision and uniformity on varying surface topographies, and the LSO technology utilizes a single-imaging technique for higher imaging quality. These enhancements are built into the revolutionary new high-precision platform and supported by advanced scaling algorithms to allow the Orbotech Corus 8M system to achieve finer resolutions – down to 8µm line width – and higher registration accuracy of ±5µm for advanced applications.

The resulting capability of the Orbotech Corus 8M system is targeted for volume-scale production of IC substrates (modules, flip-chip ball grid array [FCBGA] core layers) and advanced high-density interconnect (HDI) PCBs with compatibility to a range of advance process types like the modified semi-additive process (mSAP), as well as the tent-and-etch process.

The ability to produce ultra-fine lines with extreme accuracy makes Orbotech Corus 8M DI systems ideally suited for high-performance applications, including high-end smartphones and wearable devices like smartwatches.

The Orbotech Corus 8M system’s advanced target recognition and scaling algorithms deliver precise imaging accuracy for each sub-panel (unit level) and offer full flexibility to read any number of targets with any target layout across the panel (including asymmetrical patterns of targets) and any target type with minimal throughput loss to help deliver high productivity.

Together as One

The Orbotech Corus direct imaging solution derives its name from music lexicon.

“Just as a chorus of singers will harmonize distinct parts into a rich, unified vocal texture, Orbotech Corus DI systems harmonize myriad modules and components into a single system to achieve higher quality, yield and efficiency supporting continued innovation for PCBs and IC substrates,” Gordon says.

To learn more, click here and read our press release.

Follow Us